Seaweed hydrocolloids

Industrial gums

The terms "industrial gums" is a generic names for a range of products that are either manufactured artificially or extracted from animals or plants and used to achieve various levels of viscosity. These include polyethyleneglycolate, guar gum, xanthan gum, carboxymethylcellulose, and gelatine.

Seaweed industrial gums, also known as 'seaweed hydrocolloids', extracted from seaweeds fall into three categories: alginates (derivatives of alginic acid), agars and carrageenans. Alginates are extracted solely from brown seaweeds whilst agars and carrageenans are extracted only from red seaweeds. There are a number of artificial products said to be suitable replacements for seaweed hydrocolloids, but none have the exact gelling and viscosity properties of seaweed gums, and the certification, and it is very unlikely that seaweeds will be replaced as the source of these polysaccharides in the near future.

According to Bixler & Porse (2010), seaweed hydrocolloid markets grew at annual rates of 3-5% in the 1980s and 1990s, but, after 2000, growth rates fell to 1-3% per annum. This growth was largely driven by increased demand in China, Eastern Europe, Brazil and other emerging markets. Price increases in recent years have begun to have a dampening effect on sales, particularly in markets where substitution with less exepensive ingredients is possible. Higher costs reflect higher energy and refining chemical costs, but also seaweed shortages. The Philippines and Indonesia are the main sources of farmed carrageenan-producing seaweeds, and both are showing signs of production being limited by a range of local factors. A similar situation is emerging with brown seaweeds for alginates, and red seaweeds being used for the extraction of agars are also in limited supply, perhaps more than any other sector.

China does not produce seaweeds suitable for the higher-end food applications, and the purchase of such seaweed on the world's market by the Chinese is said to be causing supply shortages.

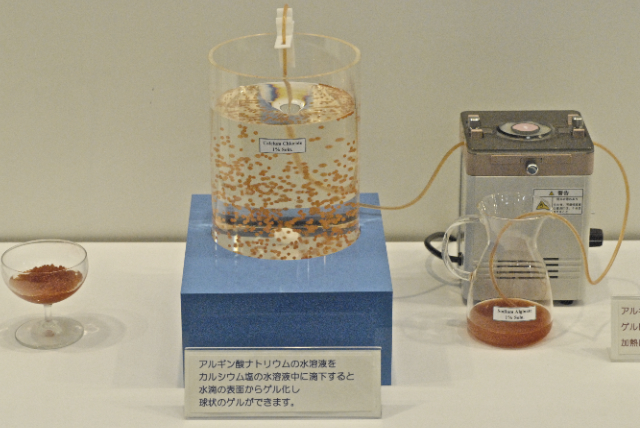

The carrageenan market in particular requires new product development on a continual basis to stimulate demand, and these product cycles have been faltering., although some heath-care developments are showing potential, particularly carrageenan gel capsules and alginate microbeads (picture above of artificial fish eggs being made from dropping sodium alginate into a calcium suplhate solution).

Seaweed hydrocolloid sales volume 1999-2014.

| Seaweed gum | 1999 sales (MT) |

2009 sales (MT) |

2014 est (MT) |

| Agar | 7,500 | 9,600 | 10,600 |

| Carrageenan | 42,000 | 50,000 | 60,00 |

| Alginate | 23,000 | 26,500 | 30,000 |

| Total | 72,500 | 86,100 | 100,600 |

Growth in seaweed hydrocolloid market from 1999-2014.

| Seaweed gum | 1999 sales ($ million) |

2009 sales ($ million) |

2014 sales ($ million) |

| Agar | 128 | 173 | 191 |

| Carrageenan | 291 | 527 | 626 |

| Alginate | 225 | 318 | 339 |

| Total | 644 | 1,018 | 1,156 |

Source: Bixler, H.J. & Porse, H. (2010). A decade of change in the seaweed hydrocolloids industry. Journal of Applied Phycology and Bixler (pers. comm.)